Classification 产品分类

Introduction 产品介绍MORE

Honeywell霍尼韦尔MIDAS四合一探测器 2020新款 Hi-Tech Products Midas-M (4 in 1) Hi-Tech Products Midas-M (4 in 1) Hi-Tech P...

FEMA KSW Air & Liquid Flow Switch KSW series is highly reliable, compact electronic flow switches are designe...

Honeywell STG700 SMARTLINE Gauge Pressure Transmitters Description Honeywell STG700 Smartline® smart pressure...

Midas® Gas Detector High Tech & Gov. Systems Bringing new visibility, reliability and ease of use to gas detec...

C300 Controller Honeywell’s C300 Controller provides powerful and robust process control for the Experion® pl...

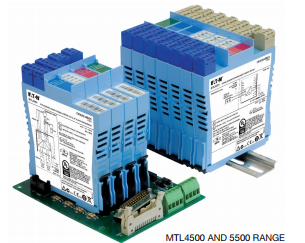

MTL4500/MTL5500 range Machine Monitor Interfaces Vibration Probes - MTL4531, MTL5531 Temperature Sensors - MT...

Fairchild PAX1 Electric Linear Actuator Features Output pressure locks in last position in event of power fai...

Ex-LED Light Fitting eLLK 92 LED LED-light fitting with twin channel LED driver. Wide input voltage range allo...

Part No Model No Description 80360206-001 CLI - Computer Gateway 80360209-001 I/O CLI 80360230-001 I/O ...

SS4 Flame Detector SSX Flame Detectors Electro-optical digital detectors represent leading edge UV and UV/IR t...

Fireye Burner Controls & Flame Scanners & Igniter Products BURNERPROTM FLAME SAFEGUARD CONTROL BURNERLOGIX® Y...

Yamatake Honeywell Advanced Multifunction Controller (AMC) Shanghai Wanchang Controls provides high quality re...

MIDAS PORTABLE Gas monitoring system for fast and reliable detection of flammable and toxic gases used in ind...

Honeywell TDC 3000 Shanghai Wanchang Controls provides high quality recycled and surplus Honeywell TDC 3000 p...

Ex-light fitting (LED and fluorescent) eLLK 92... CSA For CSA-applications. Suited for use outdoors due to hig...

INTEGRATED & DISCRETE SCANNERS Flame Scanner Products INTEGRATED SCANNERSFireye® provides a variety of UV and...

SOLID SDE Fire detection and control panel for spark extinguishing systems Product & application The SOLID Spa...

FEMA S6065 Liquid Flow Switch The S6065A1003 and S6065A2001 Liquid Flow Switches are designed for monitoring ...

Fairchild Electro-Pneumatic Transducers Accurate, compact I/P, E/P, D/P & P/I electro-pneumatic transducers w...

Part number Manufacturer Description 04293400 Honeywell Measurex Scanner Termination 2040 pcba 05120500 Honey...

Company 公司简介MORE

上海宛畅实业有限公司/Shanghai Wanchang Industrial Co., Ltd. ---全球工业机械配件优质供应商,一站式工业品采购服务商 ---Global Premium Supplier of Machinery parts, One-Stop Industrial Procurement Partner 一、公司概况/Company Overview 上海宛畅实业有限公司成立于2012年,位于中国上海市,是一家专注于工业自动化配件,分析测试仪器仪表,钢铁生产化学试剂一站式采购与技术解决方案的贸易服务商。公司依托全球供应链网络,为制造业客户提供高性价比、高可靠性的自动化零部件,覆盖钢铁,电厂,半导体光伏,汽车,石油化工等领域。 Established in 2012 and headquartered in Shanghai, China, Shanghai Wanchang Industry Co., Ltd. is a leading trade service provider specializing in one-stop procurement and technical solutions for: Industrial automation spare parts Analytical instrument and test equipment Chemical reagents for iron and steel production Leveraging a global supply chain network, we deliver cost-effective, high-reliability automation parts to manufacturers across sectors including Iron...

Contact us 联系我们MORE

E-mail: sales@parts4automation.com

Add:Room421-422,Building A,Hengjie business building, No.1234,Xinsongjiang Road, Songjiang,Shanghai,China

Tel: +86-21-37824198

Fax: +86-21-37824198 ext 8010

Partners 合作伙伴MORE

Why choose us 为什么选择我们

Talk to an engineer who understands your application. Contact us

We carry over 100 of the top brands in instrumentation. View brands

if you find a better price, let us match it. Click for details

Most orders > $100 ship FREE. $5 shipping for orders < $100. Click for details

Salesman-1

Salesman-1