Date:2017-10-19 Hits:4646

Infrared Transmitters

Infrared point hydrocarbon gas detector certified for use in potentially explosive atmospheres

Features & Benefits

Over 100,000 units installed worldwide

Improved reliability

Fast speed of response

Quick Specs

Material: 316 stainless steel

Response time: T50 < 3 seconds, T90 < 4 seconds (methane)

Operational and certified: -40° to + 65°C temperature range

Product Overview

Searchpoint Optima Plus is an infrared point Hydrocarbon gas detector certified for use in potentially explosive atmospheres. The unit’s infrared detection principle offers the fastest speed of response and fail-to-safe operation, ensuring that your plant is compliant, your personnel are protected and your production process can deliver maximum uptime. Reduced routine maintenance, when compared with conventional electro-catalytic based gas detectors, provides low ongoing cost of ownership. The development of advanced internal fault diagnostics and false alarm rejection algorithms ensures that the Searchpoint Optima Plus delivers the highest level of operational integrity.

Typical Applications

Offshore oil and gas platforms, floating production storage and offloading (FPSO) vessels, tankers, onshore oil and gas terminals, refineries, LNG/LPG bottling plants, gas compressor/metering stations, gas turbine power plants, solvent printing and coating plants.

Over 100 gas and vapor calibrations available. For a list of gases and vapors that Searchpoint Optima Plus can detect, contact your local distributor.

Additional Features and Benefits:

Why Searchpoint Optima Plus is the right choice...

Experience gained from over 100,000 units installed worldwide

Improved reliability

Optional HART® over 4-20mA output

Can detect a wide range of hydrocarbon gases including solvents

Increased reliability with no moving parts

Increased stability from self compensating optics

Immune to long term component drift

Remote functional gas test facility

Certified for North American and European Hazardous areas

Increased false alarm rejection

Increased uptime with contaminated optics warning

Dynamic Heating Control ensures condensation free optics

No undetected failures

Improved diagnostics

Integral event logging

Reduced power consumption

Certified to many hazardous area classification schemes including: UL, CSA, ATEX, IECEx and more

Why Infrared?

Failsafe operation

Fast speed of response

Reduced routine maintenance

Immune to catalytic poisons

Long operating life

Works in inert atmospheres

Advanced infrared

point gas detector

Failsafe Hydrocarbon

Gas Detection

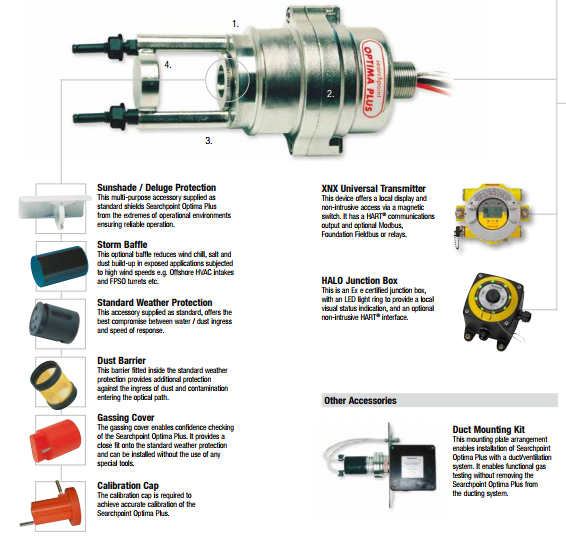

1. Optics Block

The 4-channel (dual compensated) optics-block is the

heart of the Searchpoint Optima Plus. It is specifically

designed to compensate for changes in the external

environment similar to 2-channel designs, but also

compensates for long term component drift such as

infrared sources and detectors. This provides the

Searchpoint Optima Plus with the most stable optics

design possible.

2. Microprocessor

The microprocessor controls the operation of the

Searchpoint Optima Plus. The signal processing

and algorithms provide a new dimension in false

alarm rejection delivering the highest level of

operational integrity.

3. Heated Optics Plus Dynamic

Heating Control

Heated optic components, monitored via smart

electronics, eliminate condensation build up with power

saving features.

4. Remote Gassing Cell

Factory fitting of this optional gassing cell within

the optical path allows the remote injection of

functional test gas to validate the performance of

a Searchpoint Optima Plus.

Remote Gas Sampling Systems

For monitoring remote or inaccessible locations

Searchpoint Optima Plus can be fitted with a flow housing

and engineered into a gas sampling system. Single-point

and multi-point systems are available for both hazardous

and non-hazardous areas.

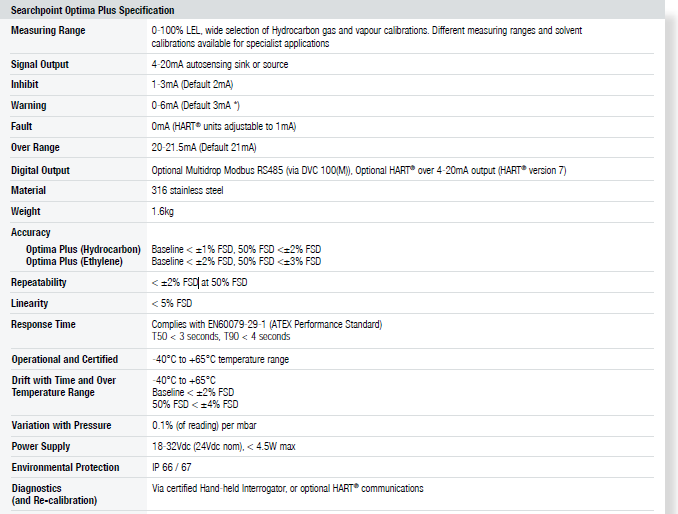

Searchpoint Optima Plus Specification

Measuring Range 0-100% LEL, wide selection of Hydrocarbon gas and vapour calibrations. Different measuring ranges and solvent calibrations available for

specialist applications

Signal Output 4-20mA autosensing sink or source

Inhibit 1-3mA (Default 2mA)

Warning 0-6mA (Default 3mA *)

Fault 0mA (HART® units adjustable to 1mA)

Over Range 20-21.5mA (Default 21mA)

Digital Output Optional Multidrop Modbus RS485 (via XNX, Optional HART® over 4-20mA output (HART® version 7)

Material 316 stainless steel

Weight 1.6kg

Accuracy

Optima Plus (Hydrocarbon) Baseline < ±1% FSD, 50% FSD <±2% FSD

Optima Plus (Ethylene) Baseline < ±2% FSD, 50% FSD <±3% FSD

Repeatability < ±2% FSD at 50% FSD

Linearity < 5% FSD

Response Time T50 < 3 seconds, T90 < 4 seconds (methane)

Operational and Certified** -40°C to +65°C temperature range

**CU-TR-EX (Russia) Approval – XTC Version, Certified Temperature Range -60°C to + 65°C

Long Term Stability

(as defined in

EN 60079-29-1)

Baseline Methane 100 %LEL Range: ≤ ± 2 %FSD

Ethylene 100 %LEL Range: ≤ ± 4 %FSD

50 %FSD Methane 100 %LEL Range: ≤ ± 4 %FSD

Ethylene 100 %LEL Range: ≤ ± 5 %FSD

Drift Over Temperature

Range (-40 °C to 65 °C)

Baseline ≤ ± 2 %FSD

50 %FSD Methane 100 %LEL Range: ≤ ± 0.131 %FSD per °C

Ethylene 100 %LEL Range: ≤ ± 0.078 %FSD per °C

Variation with Pressure 0.1% (of reading) per mbar

Power Supply 18-32Vdc (24Vdc nom), < 4.5W max

Environmental Protection IP 66 / 67

Diagnostics Via certified Hand-held Interrogator, XNX or optional HART® communications

(and Re-calibration)

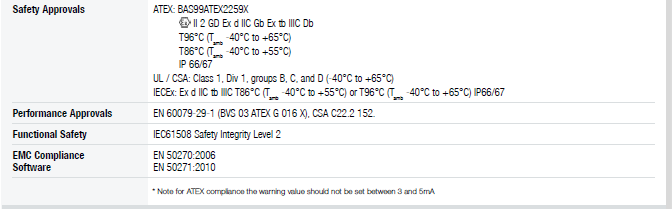

Safety Approvals ATEX: Baseefa13ATEX0296X

II 2 GD Ex d op is IIC Gb Ex tb IIIC Db

T96°C (Tamb -40°C to +65°C)

T86°C (Tamb -40°C to +55°C)

IP 66/67

UL / CSA: Class 1, Div 1, groups B, C, and D (-40°C to +65°C)

IECEx: II 2 GD Ex d op is IIC Gb Ex tb IIIC Db T86°C (Tamb -40°C to +55°C) or T96°C (Tamb -40°C to +65°C) IP66/67

CU-TR-EX (Russian Customs Union) - XTC Version 1Ex d op is IIC T5/T4 Gb X (Tamb -60°C to +65°C)

Performance Approvals EN 60079-29-1 (BVS 03 ATEX G 016 X), CSA C22.2 152., FM ANSI/ISA-12.13.01.,Russian Pattern Approval (Metrology) - XTC Version ***

Functional Safety IEC61508 Safety Integrity Level 2

EMC Compliance EN 50270:2006

Software EN 50271:2010

Marine Approvals Marine Equipment Directive (MED), type approvals from DNV, BV, ABS, Lloyd’s Register

* Note for ATEX compliance the warning value should not be set between 3 and 5mA

*** Please refer to manual for full information

Salesman-1

Salesman-1